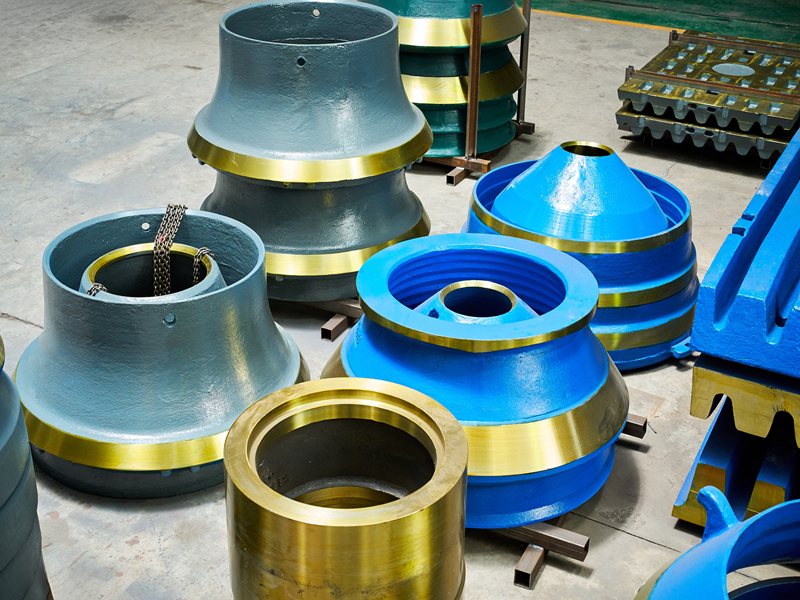

SBM /Liming VSI7611 Crusher Parts By Qiming Casting

What Is VSI7611 Crusher?

The VSI7611 sand-making machine is a very popular sand-making machine in China and other countries. The main manufacturers of this type of sand-making machine are Shanghai Shibang Machinery and Henan Liming Heavy Industry. Its parameters:

| Model | Soft material | Hard material | Side and central feeding | Fully central feeding | Speed (r/min) | Power (kW) | Overall dimension (mm) |

| Maximum feeding size (mm) | Throughput (t/h) | ||||||

| VSI7611 | 35 | 30 | 120-180 | 60-90 | 1700-1890 | 55×2 | 4100×2250×2258 |

What are VSI7611 Crusher Parts?

There are hundreds of spare parts in the VSI7611 sand-making crusher, the below is the part list:

| Ser. | Name | Part Number | Material | QTY/SET | Unit Weight(Kg) |

| 1 | Motor pulleys | VSI7611-2-101 | HT | 2 | 72.5 |

| 2 | Spindle pulleys | VSI7611-6-101 | HT | 1 | 91 |

| 3 | Bearing locating cylinders | VSI7611-6-107 | HT | 1 | 50 |

| 4 | Bearing cylinders | VSI7611-6-106 | QT | 1 | 320 |

| 5 | Positioning plate on bearing cartridge (Upper) | VSI7611-5-117 | ZG | 1 | 106 |

| 6 | Positioning plate on bearing cartridge (Down) | VSI7611-5-116 | ZG | 1 | 83.5 |

| 7 | Lower seal sleeve | VSI7611-6-102 | ZG | 1 | 8 |

| 8 | Lower bearing cap | VSI7611-6-102 | ZG | 1 | 35.5 |

| 9 | Upper bearing cap | VSI7611-6-110 | ZG | 1 | 38 |

| 10 | Flip wheel mouth guard | VSI7611-8-102 | ZG65Mn | 1 | 31 |

| 11 | Discharge liner ring | VSI7611-3-101 | ZGMn13Cr2 | 12 | 3 |

| 12 | Impact blocks | VSI7611-3-102 | ZGMn13Cr2 | 24 | 20 |

| 13 | Upper strike guard | VSI7611-3-105 | ZGMn13Cr2 | 24 | 11.5 |

| 14 | Hopper liner rings | VSI7611-3-111 | ZGMn13Cr2 | 5 | 1.5 |

| 15 | Lower strike guards | VSI7611-3-112 | ZGMn13Cr2 | 24 | 8.3 |

| 16 | Upper runner plates | VSI7611-8-103 | ZGMn13Cr2 | 3 | 6.2 |

| 17 | Lower runner plates | VSI7611-8-104 | ZGMn13Cr2 | 3 | 9.5 |

| 18 | Wear-resistant plates | VSI7611-8-107 | ZGMn13Cr2 | 3 | 1.6 |

| 19 | Feeding tube | VSI7611-3-110 | Chrome Steel | 1 | 15 |

| 20 | Impact blocks | VSI7611-8-106 | Chrome Steel | 9 | 1.1 |

| 21 | Dividing cones | VSI7611-8-105 | Chrome Steel | 1 | 26.5 |

| 22 | Protection plates | VSI7611-8-108 | Chrome Steel | 9 | |

| 23 | Rotor tips | VSI7611-8-2-101 | 42CrMo+Alloy Bars | 3 | 3.5 |

| 24 | Main shaft | VSI7611-6-108 | 35Crmo | 1 | 138 |

| 25 | Bearing cylinder assembly | VSI7611-6 | 1 | ||

| 26 | Rotor assembly | VSI7611-8-1 | 1 | ||

| 27 | Hydraulic integration block | HT | 1 | ||

| 28 | Upper dust pan | VSI7611-6-111 | ZG | 1 | |

| 29 | Rotor impellers | VSI7611-8-1-1 | 1 | ||

| 30 | Lower Bushings | VSI7611-3-4-1-102 | 1 | ||

| 31 | Upper bushings | VSI7611-3-4-1-104 | 1 | ||

| 32 | Handwheels | VSI7611-3-5-111 | HT200 | 1 |